日本羽毛製造のものづくり1983年の創業以来、弊社は国内・自社生産にこだわって それは、ひとつの製品を最初から最後まで自分たちで作り、 遠い国の知らない誰かに作業をゆだねたり、 たくさんの人に商品を届けるため、効率化を心がけながらも、 そんな私たちの工場をご案内いたします。 |

Our commitment to manufacturingSince our founding in 1983, we have persisted in domestic and in-house production of our products. This dedication stems from our desire to carefully craft each item from start to finish, akin to handing it over to friends and family. We aim to infuse our work with heart and skill, eschewing outsourcing to distant lands and the impersonality of mass production in large factories. While considering efficiency in order to reach as many people as possible, we place importance on creating products that resonate with individuals. Allow us to introduce you to our factory embodying these principles. |

Jumouファクトリー目次

- 羽毛の衣類と小物/Down clothing & accessories

商品企画/Planning → 素材選び/Selecting Materials → パターン作成/Pattern Creation → 裁断/Cutting → 縫製/Sewing → 羽毛の充填/Filling →仕上げ/Finishing → 検品/Inspection - 羽毛の寝具/Feather bedding

材料の確保/Securing materials → 側生地の縫製/Sewing → 羽毛の充填と仕上げ/Filling & Finishing → 検品と出荷/Inspection & Shipping - 羽毛再生とメンテナンス事業/Feather recycling and maintenance

羽毛再生事業/Feather recycling

羽毛の衣類と小物/Down clothing & accessories

創業当初は羽毛布団専門の下請け工場でしたが、長年羽毛のすばらしさに触れるなかで、「睡眠時ばかりでなく日常の様々な場面で、もっと羽毛を役立てていただきたい」と考えるようになりました。 そしてくつろぎの時間はもちろん、寒い職場や屋外での活動時に冷えから体を守れたら…と、羽毛の衣類や小物の製造にも力を入れています。 きめ細やかにお客さまのニーズにお応えし、小ロットからでも製造に着手できることが私たちの強みです。 本社ビル3階の工場を中心に操業しているアパレル部門の製造現場をご紹介いたします。 |

When we first started, we were a subcontractor factory specializing in down comforters, but after experiencing the wonders of down for many years, we began to think that “we want people to use down more not only during sleep but also in various aspects of everyday life.” And so, we now focus on producing down clothing and accessories that provide warmth and comfort not only during relaxation but also in cold workplaces and outdoor activities. Our strengths are our ability to meticulously meet customer needs and begin manufacturing even for small lots. We would like to introduce you to the manufacturing site of our apparel division, which operates primarily on the third floor of our headquarters building. |

| →アパレルブランドサイトへはこちらから | → Click here to go to the apparel brand site |

商品企画 |

Planning |

|

羽毛には、体を冷えから守り、心までも温める力がある。 冷えに苦しむ人に暖かさをお届けし、おしゃれをあきらめることもないようにしたい。 美しいデザインに惹かれて商品を手に取ってくださった方が、着てみて、その軽さと暖かさに感動する。そんな様子を思い浮かべ、わくわくしながら新しい商品を考えています。 お客さまの「こんなの、あったらいいな」から商品が生まれることもあります。 羽毛入りの衣類や小物について、ご意見、ご要望も歓迎いたします。 もちろんアパレル関係業者の方からのダウンパックのご注文も承っております。お気軽にお問合せください。 |

We believe that down has the power to protect the body from the cold and warm the heart.. This belief guides our approach to working with this material. We aim to deliver warmth to those suffering from the cold, without requiring them to sacrifice style. We envision the delight of someone who, attracted by the beautiful design, picks up one of our products and is then amazed by its lightness and warmth upon wearing it. This image excites us as we brainstorm new products. Sometimes products are born from customers’ wishes of “I wish there was something like this.” We welcome your opinions and requests regarding down-filled clothing and accessories. Of course, we also accept orders for down packs from apparel-related businesses. Please feel free to contact us.

|

| →OEMのお問合せについてはこちら | →Click here for OEM inquiries |

素材選び |

Selecting Materials |

|

保温力や通気性など、羽毛の特長を生かすと同時に、肌触り、柔軟性など、着心地の良さを実現しやすい素材選びを心がけています。 再生繊維やオーガニックコットンなど、サステナブルな素材も積極的に取り入れます。 色、柄も、手にした人、着用する人がうれしくなるようなデザインになることをめざして選んでいます。 羽毛製品の目的は防寒だけではなく、着用時の活動のしやすさ装いの美しさも損なわないことが大切と考えています。 |

We aim to select materials that not only utilize the features of down, such as heat retention and breathability, but also ensure comfort through qualities like texture and flexibility. We actively incorporate sustainable materials, including regenerated fibers and organic cotton. The colors and patterns of our products are selected with the aim of creating designs that will make people who hold and wear them happy. We believe that the purpose of down products is not only to provide warmth but also to ensure ease of movement and maintain the beauty of the wearer’s outfit. |

| →サステナブルについての弊社の方針はこちらから | → Click here for our policy on sustainability |

パターン作成 |

Pattern Creation |

|

弊社工場にはパタンナーが常駐しており、 新商品開発時にはスタイル、着心地の良さなど 同型商品のバリエーションを制作する場合でも |

Our factory has pattern makers on site, allowing us to quickly turn ideas into tangible forms. During the development of new products, we repeatedly create prototypes until we are satisfied with the style and comfort. Even when producing variations of the same model, adjustments are necessary depending on the thickness and texture of the fabric. In such instances, our experienced pattern makers showcase their skills. |

裁断 |

Cutting |

|

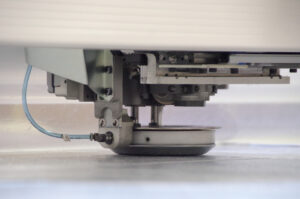

原則として長方形である寝具類とは異なり、 細かい凹凸、曲線などを正確に切り取るのは、 その作業を効率化するために、弊社では自動裁断機を採用しています。 |

Unlike bedding, which is generally rectangular, Precisely cutting fine contours and curves is a highly labor-intensive task when done by hand, especially when dealing with dozens or hundreds of pieces. To streamline this process, we employ automated cutting machines at our factory. |

|

■使用機器

積層式自動裁断機:P-COM161S

【特長】

|

■Stacking automatic cutter: P-COM161S [Features]

|

自動裁断機:P-CAM161S |

カッティングヘッド |

裁断生地の吸引固定 |

縫製 |

Sewing |

|

羽毛製品の特殊な縫製に熟練した職人によって 表地は厚さも伸縮性も様々な素材を用いるため、 またミシンも様々なタイプの工業用ミシンを揃え、あらゆる形状を 精緻に縫い上げています。 |

Each product is carefully sewn by skilled craftspersons who specialize in the unique sewing techniques required for down products. Our factory also manufactures many new types of down clothing that incorporate down packs and have quilting seams that do not appear on the outside. The outer fabrics are made from a variety of materials with different thicknesses and elasticity, so high skill is required to sew them accurately. This is where our manufacturing staff’s skills are put to the test. We also have a wide variety of industrial sewing machines, which allow us to sew all kinds of shapes with precision. |

|

■使用中の主な機器

|

|

|

|

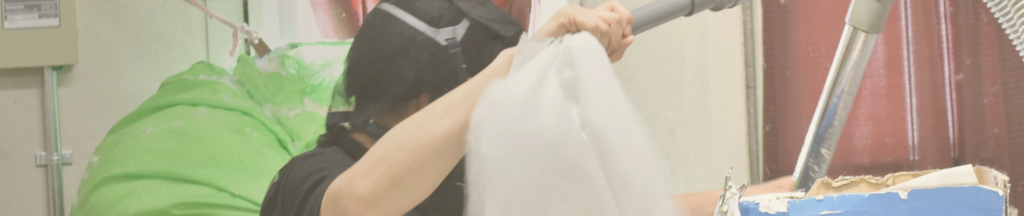

羽毛の充填 |

Filling |

羽毛が最大限に「開く」のを妨げず、なおかつ全体に行きわたる絶妙な量を各パーツに充填する必要があります。 ここで使用される量りは羽毛を0.1g単位で正確に計量することができる電子天秤で、羽毛布団の羽毛を充填するときに使われるものとは異なる機種です。 計量された羽毛は空気とともにキルティングを施した生地内に送られ、小さいパーツには手作業で羽毛を詰めて、ふっくらと膨らんだダウンパックまたは製品となります。 |

It is not the case that a down product will be warm just by stuffing it with a lot of down. Each part needs to be filled with the perfect amount of down so that it does not prevent the down from spreading out to its full extent and yet spreads evenly throughout. The scale used for this process is electronic balance that can measure down to an accuracy of 0.1g, which is different from the model used for filling down comforters. The measured down is then sent into the quilted fabric with air, and smaller sections are manually stuffed with down resulting in a plump and fluffy down pack or product. |

仕上げ |

Finishing |

|

「口縫い」と呼ばれる工程です。 羽毛を充填する製品は、縫製の時に充填口を残しておき、羽毛を充填したのちに口を閉じる作業をします。 製品を少しぐらいつぶしたり掴んだりしても羽毛がはみ出してくることのないようにしっかり閉じます。 信頼できる商品を作るために、地味ですが大切な作業です。 |

This is a process called “sewing the mouth.” For products that are to be filled with feathers, a filling opening is left during sewing, It is tightly sealed so that the feathers will not spill out even if the product is slightly crushed or grabbed. This is a simple but important process in order to make reliable products. |

検品 |

Inspection |

|

縫製のエラーや生地の汚れなどがないか、一枚一枚、丁寧に検品しています。 また破損したミシン針など金属片が残っていないか、検針機により入念にチェックします。 検品は品質を確保するために注意深く行います。 |

We carefully inspect each item to ensure We also use a needle detector to thoroughly check for any remaining metal pieces, such as broken sewing needles. Inspection is carried out carefully to ensure quality. |

羽毛の寝具/Feather bedding

|

弊社は40年以上にわたり、羽毛布団の製造に携わってまいりました。 その多くは病院や福祉施設、ホテルなど宿泊施設向けの業務用羽毛布団、そしてOEMや通販向けの製品です。 熟練の職人技に直接アクセスできる私たちの工場をご紹介いたします。 |

Our company has been manufacturing down comforters for over 40 years since its founding. Our products mainly consist of commercial down comforters for hospitals, welfare facilities, hotels, and other accommodation facilities, as well as OEM and mail-order products. However, we also accept inquiries from general customers over the phone or in person, taking advantage of our strength in being able to carefully handle requests for small quantities. We will introduce you to factories where you can find futons made by skilled craftspersons. |

材料の確保/Securing materials |

|

|

|

側生地の縫製/Sewing |

|

|

|

羽毛の充填と仕上げ/Filling & Finishing |

|

検品と出荷/Inspection & Shipping |

|

羽毛再生とメンテナンス事業/Feather recycling and maintenance

羽毛再生事業

詳しくは下記のページをご覧ください。

Feather recycling

For more information, please see the page below.